We are working hard to make products that are environmentally friendly

and to further develop our environmental management systems.

The momentum to protect the global environment is growing worldwide. Along with the role of papermaking equipment in reducing the environmental impact, environmental initiatives have come into focus in equipment manufacturing as well. Ichikawa adopted an environmental management system at an early stage and obtained ISO 14001 certification at the Kashiwa Mill in March 2000 and the Iwama Mill in May 2019. Under three main themes—conserving energy to reduce electricity and gas use, conserving resources to reduce wastewater volume, and recycling to reduce industrial waste—we are proactively developing environmental initiatives that include reducing our use of chemicals.

Basic Policy

Ichikawa contributes to the development of society as a papermaking equipment manufacturer. We also consider environmental conservation as an important management issue. Through company operations, we work together with all employees to improve global environmental conservation, as we develop sustainability.

Environmental Code of Conduct

- Fully comply with all environment laws and regulations; establish voluntary management standards, as needed; and work to prevent environmental pollution.

- During all production processes and while supplying products and services, work to save energy, reduce use of resources and waste, etc.

- For product development and in the design stages, we predetermine the environmental impact when selecting materials, as well as while manufacturing and using them. Our products help conserve the environment, within what is technically and financially feasible.

- We set environmental goals and targets, while continually maintaining operations and improving, to execute initiatives that reduce our environmental impact..

- Through environmental training, we educate all employees on our policies, as we work to raise awareness of the environment and promote conservation across the company.

Promotion System

Ichikawa has established the Environment and Energy Conservation Action Communication Committee to promote overall improvement.

* The Ibaraki Eco Office Registration System is a system under which companies undertake environmentally conscious initiatives set by Ibaraki Prefecture, and become registered after examination by the prefecture.

As a comprehensive solutions company for the press section, Ichikawa manufactures and sells papermaking equipment and industrial felts that are indispensable for making paper.

Energy Conservation, Global Warming Mitigation, and Environmental Initiatives

Ichikawa is promoting the following initiatives for reducing CO2 and conserving energy.

CO2 reduction and energy conservation

- Use of alternative energy sources

- Increased adoption of liquefied natural gas (LNG)

- Transition to high-efficiency equipment

- Improved production efficiency

Transitioning to Renewable Energy

Switching all purchased energy to renewable energy (Kashiwa and Iwama Mills)

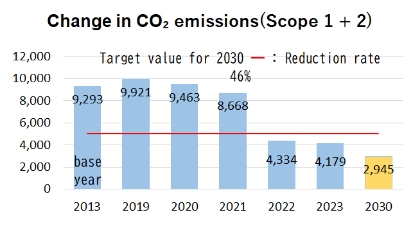

Guided by the revised plan to achieve carbon neutrality by 2050, we have updated our target of reducing CO2 emissions by 46%, compared with fiscal 2013 levels, by 2030. So, we have effectively switched to renewable energy by purchasing 100% renewable electricity at every business site. Since October 2021, our Head Office, Kashiwa Mill, and the R esearch & Development Department have been using renewable energy with nonfossil fuel certificates (with tracking), and since April 2022 the Iwama Mill has also been using renewable energy.

Installation of self-consumption solar power generation systems (Kashiwa and Iwama Mills)

Iwama Mill: photovoltaic power generation equipment (200 kW)

Kashiwa Mill: photovoltaic power generation equipment (500 kW)

Introduction of co-generation system (CGS) (Kashiwa Mill)

Kashiwa Mill: Gas cogeneration system

The Kashiwa Mill began operating a gas cogeneration system in fiscal 2006 to reduce CO2, and we upgraded to a highly efficient system and expanded the use of waste heat in 2020 to raise overall efficiency by 15% (power generation efficiency and waste heat recovery rate). This is contributing to a significant reduction in CO2 while providing 70% of the electricity we use.

Expanded Adoption of Natural Gas (City Gas)

Switched fuel use (Scope 1) to natural gas (Kashiwa and Iwama Mills)

The fuel used in our production plants has been fully switched to natural gas, which generates less CO2 emissions.

Introduction of gas heat pump (GHP) air conditioning systems (Head Office, Kashiwa and Iwama Mills)

To stabilize electricity demand, we introduced gas heat pump (GHP) air conditioning systems at every business site.

Transition to high-efficiency equipment (Head Office, Kashiwa and Iwama Mills)

- We are promoting the transition to low-power consumption LED lighting and have completed this transition at nearly all our facilities.

- We are shifting to low consumption, high-efficiency air conditioning.

- We are also adopting new low consumption, high-efficiency motors and electrical components for production.

Enhancing production efficiency

- We are evolving automation for increased productivity.

- We are developing and implementing medium- to long-term equipment plans to upgrade production for higher efficiency.

Change in CO2 Emissions

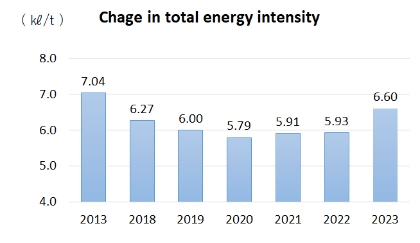

Change in Total Energy Intensity

Reduced Water Use (Kashiwa and Iwama Mills)

We are reducing water use by converting to on-machine cleaning systems at the Kashiwa Mill and introducing a wastewater recycling system at the Iwama Mill. Particularly at the Iwama Mill, we are recycling 95% of the wastewater used during production.