New value for industrial felts, based on advanced press felt manufacturing technology

Industrial-use felts are a range of high-performance products developed based on manufacturing techniques for paper felts and made from high-performance fibers featuring superior heat resistance, abrasion resistance and strength. Ichikawa’s industrial felts support sophisticated production centers in the aluminum extrusion, printed circuit boards (electronics), and iron manufacturing industries, in Japan and around the world.

Products by purpose

Heat-resistant cushioning material (Ace Board®)

Ace Board® combines high heat resistance with sustained cushioning properties for use in the high-temperature press molding of printed circuit boards. Ace Board® provides optimal heat resistance and cushioning tailored to press temperatures. We offer a wide range of materials and specifications to suit your specific usage conditions.

Ace Board® is widely used in the production of cutting-edge printed circuit boards for next-generation communication standards, IoT, and CASE applications, where technological innovation is rapidly advancing.

In addition to printed circuit boards, Ace Board® is also used as a cushioning material in various high-temperature press applications, including electronic components and building materials.

Features of Ace Board®

Ace board® is a high performance heat-resistant cushioning material made from highly heat-resistant fibers.

Excellent cost performance

- Maintains superior cushioning properties: Extended lifespan

- Environmentally friendly: Significantly reduces waste

- Improved workability: Substantially reduces man-hours

- Non-gassing: Does not emit harmful gases

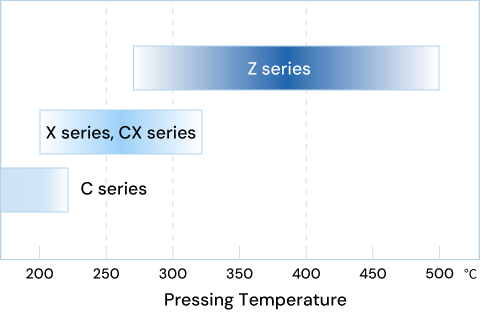

Ace Board® C Series: Up to 220°C

Basic cushioning material suitable for presses up to approximately 220°C, offering cost reductions and environmental benefits

Ace Board® X and CX Series: Up to 300°C

Cushioning materials for presses up to approximately 300°C, offering cost reductions and environmental benefits

Ace Board® Z Series: Up to 450°C

Super cushioning material capable of withstanding presses up to approximately 450°C, making it suitable for high-temperature molding of high heat-resistant boards

Temperature Range Compatibility

Application Examples

In the printed circuit board manufacturing process, there's a press molding step in which copper foil and prepreg (interlayer insulation material) are laminated and bonded together in a press machine. If heat and pressure are not applied uniformly, wrinkles or voids may occur, causing process defects. To prevent this, the materials are sandwiched between cushioning materials with appropriate cushioning properties and pressed uniformly. As press molding is performed at high temperatures, heat resistant cushioning materials suitable for the press temperature are used.

ACE BOARD® provides optimal heat resistance and cushioning properties tailored to the press temperature. We offer a variety of materials and specifications to suit your usage conditions. We also provide types that can be press-molded at high temperatures of 300°C or above, and types with an air-impermeable surface layer for automated transport using suction.

-

Ace Board® Z Series: Up to 220°C

Used in the manufacture of CEM-1, CEM-3, and FR-1 boards

-

Ace Board® Z Series: Up to 300°C

Used in the manufacture of FR-4, BT resin, and PPE boards

-

Ace Board® Z Series: Up to 450°C

Used in the manufacture of LCP and fluorine resin boards.

Ace Board® is also used in other electronic component manufacturing processes requiring heat pressing.

Heat-Resistant Conveying Material: For Aluminum Extrusion (THERMOTEX®)

In aluminum extrusion lines for building materials and precision parts, aluminum is molded at a high temperature of over 500°C and must be transported without causing scratches or distortions. Ichikawa's THERMOTEX® is widely used in the aluminum extrusion industry as a material for transporting high-temperature products.

Application Examples

Extruded aluminum profiles are gradually cooled as they pass from the initial table through the run-out table, cooling table, and saw table. For this reason ,we offer an range of felts made from various types of fibers to match the temperature and transportation conditions of the extruded aluminum profiles.

We can accommodate the following temperature ranges:

- PBO and para-aramid fiber laminate type: Up to 550°C (contact)

- Para-aramid fiber type: Up to 450°C (contact)

- Meta-aramid fiber type: Up to 250°C (contact)

- Polyester fiber type: Up to 130°C (contact)

We offer three product types:

- Tubes

- Belts (endless and jointed)

- Pads

Roll Cover for Galvanizing Lines: Felt for Steel Plates

In continuous galvanizing lines for steel plates, the steel plate galvanized in the zinc pot reaches temperatures of over 400°C. When the heated steel plate passes through rolls, it is still around 250–400°C, making it susceptible to damage from roll contact. The roll is therefore covered with felt to prevent scratches. This is the felt for steel plates.

Application Examples

The felt is wrapped around the roll and fixed by folding both ends. Adding extra felt to the contact area (crown part) as the part in contact with the steel plate gradually wears thin can extend the lifespan and prevent steel plate meandering.

Other Products

- Other heat-resistant conveying materials: For dyeing and finishing (fabric)

- Heat-resistant wiping materials: Water removal wipers for hot rolling rolls

- High-performance filtration materials: For roll press dewatering machines

Ichikawa's industrial felts are used in various production lines, including steel manufacturing lines and high-end fabric processing where texture is crucial. You may be surprised to discover that Ichikawa's industrial felts are hard at work in your everyday surroundings.

Download catalog here