Ichikawa will continue to explore the potential of shoe press belts with manufacturing facilities accommodating all sizes and unique, progressive technologies.

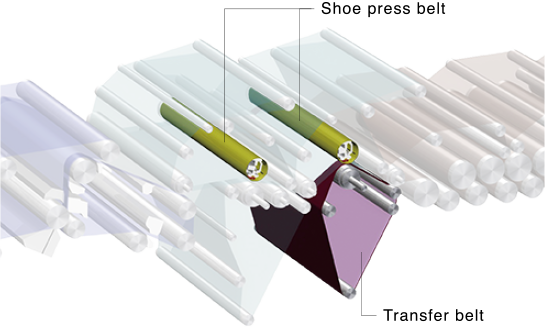

There is a growing demand for high-value-added paper production with exceptional cost competitiveness amid the globalization of the papermaking market, and there has been a trend for adopting shoe press mechanisms in the press section. The main feature of the shoe press mechanism is superior dewatering compared with conventional paper machines. In 1988, Ichikawa was the first domestic manufacturer to successfully develop a shoe press belt. Since then, we have continually transformed our performance with proprietary technology, achieving long life through superior dewatering, durability, and operational stability, while meeting the needs of the times. In 1998, our achievements were recognized with the prestigious Sasaki Award from the Japan Technical Association of the Pulp and Paper Industry. Currently, Ichikawa’s shoe press belts are used in over 700 units worldwide, earning unwavering trust from customers across various regions. Leveraging our accumulated technical expertise and

state-of-the-art manufacturing, Ichikawa will further expand the range of products tailored to meet our customers’ needs.

Product Lineup

Ichiriki Series

Achieving long life with high-performance resins

To meet the trend towards higher speed and nip pressure in paper machines, we present the Ichiriki series featuring high-performance resins on both the felt and shoe sides. The Ichiriki series has exceptional resistance to cracking, abrasions, chemicals, and delamination on the shoe side, all crucial for achieving extended durability. This series is compatible with any shoe press size of paper machine.

IX-F

Standard type with a proven track record

This standard type combines the abrasion resistance and crack resistance necessary for shoe press belts. Depending on usage conditions, you can choose between abrasion-resistant and crack-resistant types.

Groove specifications that suit your requirements

Ichikawa’s deep understanding of the press section allows us to recommend the optimal combination of felts and belts to meet customer requirements. Groove specifications, which significantly influence the dewatering performance of the belts, can be selected from a diverse lineup to match the operating conditions of paper machines. In addition to continuous grooves of various shapes, we also offer discontinuous grooves that effectively manage backwater for high paper weights or during low-speed paper production.