With a global vision in mind, we are developing new, advanced technologies that combine our accumulated knowledge and expertise.

Product Design

Papermaking tools vary in their required functions and specifications depending on the type of paper machine, the paper being produced, and the operating conditions. Our experienced sales and technical staff, who possess specialized knowledge, work together as a team to propose and provide the optimal combination of papermaking tools, ensuring maximum efficiency in the press section of your operations.

Research and Development

Papermaking tools, such as felts and shoe press belts, are required more and more to have advanced features as paper becomes more diverse and as quality and functionality improve. In our Research and Development Department, we address these needs by researching fundamental technologies, including raw materials, structural design, and manufacturing techniques.

In 2023, to streamline the development of our products, we relocated R&D to the Kashiwa and Iwama Mills, both major production sites for papermaking felts, shoe press belts, and industrial products.

We are also focusing on developing prototypes and gathering data for future commercialization, drawing on a wide array of technical information, including new materials, state-of-the-art analytical tools, and advanced manufacturing technologies.

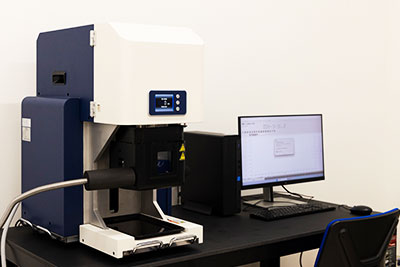

R&D Equipment

Scanning election microscope

Confocal microscope

DMS

Press simulator

Manufacturing Processes

We meet the needs of the paper industry with our state-of-the-art production facilities and products made by skilled craftsmen.

Quality Initiatives

To deliver high-quality products, we have introduced a quality management system called QMS that all departments are involved in.